JYTOP is a leading manufacturer of AAAC Conductor in the field of power transmission and distribution

With over 30 years production experience and 15 years export experience, factory price without any third party. Can be customized your ideal size,meets or exceeds the requirements of all international standards like ASTM, AS, BS, CSA, DIN, IEC, NFC, SS -etc

JYTOP's AAAC Conductor have been exported to many countries and regions such as the Middle Est, Africa, Asia Oceania, South America, North America etc., and have won praise from domestic and foreign customers.

In this page, we'll introduce AAAC Conductor and their advantages, applications, standards and frequently asked questions.

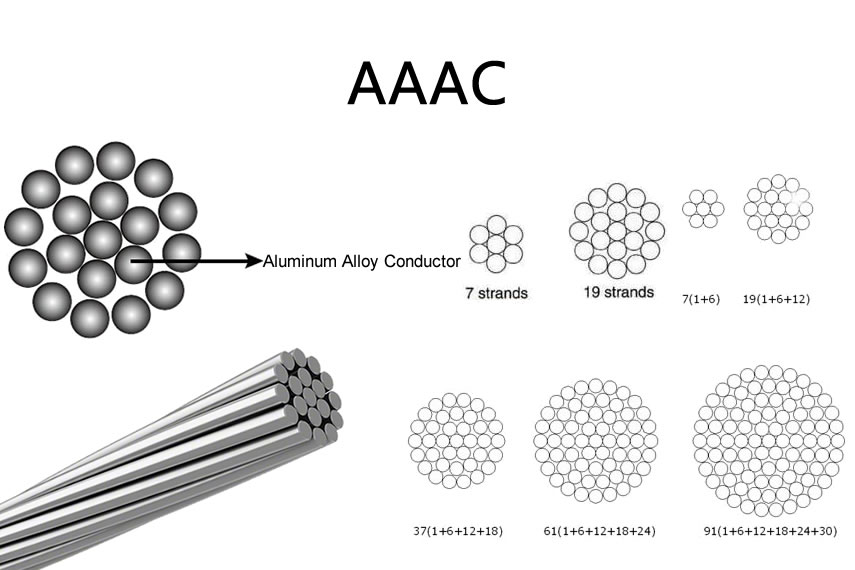

AAAC stands for All Aluminum Alloy Conductor, which is a type of overhead power transmission cable made of aluminum alloy wires. Unlike traditional overhead cables, which are typically made of aluminum or steel wires, AAAC conductors are made of an alloy of aluminum with other elements like magnesium, silicon, or zinc. This alloy composition provides several advantages over traditional cables, including improved strength, corrosion resistance, and better electrical conductivity.

AAAC conductors are often used in high-voltage power transmission lines, as they can carry higher currents and have lower resistance than equivalent size cables made of aluminum or steel. They are also commonly used in coastal and humid areas where corrosion resistance is essential.

aaac wire,aaac cable,aaac conductor,All Aluminum Alloy Conductor,All Aluminum Alloy Cable,A2(AASC) Conductor,AASC Conductor

AAAC conductors provide a higher strength to weight ratio than traditional AAC conductors, and better corrosion resistance than ACSR conductors.

JYTOP can manufacture & supply AAAC on Non returnable wooden/steel reels or Returnable steel reels.

JYTOP can produce AAAC Wire according to various domestic and international standards and customer requirements, including BS, IEC, ASTM,DIN and other standards. We can also provide customized services according to customer’s special requirements to meet the needs of different customers.

Get all the answers to the most frequently asked questions (FAQs) regarding AAAC Cable sizes,AAAC Cable full form,AAAC Conductor size chart,AAAC Conductor chart,AAAC Conductor sizes,AAAC Conductor size chart,AAAC Conductor full form,AAAC Conductor ampacity,AAAC Conductor diameter,AAAC Conductor types,AAAC Conductor data sheet and much, much more.

| Code Word | Size (KCMIL) | Stranding | Individual Wires Diameter (ins.) | Complete Cable Diameter (ins.) | Weight Per 1000 Feet (lbs.) | Rated Strength (lbs.) | Resistance OHMS/1000ft. DC @ 20°C | Resistance OHMS/1000ft. AC @ 75°C | Allowable Ampacity+ (Amps) | ACSR With Equivalent Diameter Size | ACSR With Equivalent Diameter Stranding (Al/Stl) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Akron | 30.58 | 7 | .0661 | .1980 | 28.5 | 1110 | .659 | .785 | 107 | 6 | 6/1 |

| Alton | 48.69 | 7 | .0834 | .2500 | 45.4 | 1760 | .414 | .493 | 143 | 4 | 6/1 |

| Ames | 77.47 | 7 | .1052 | .3160 | 72.2 | 2800 | .260 | .310 | 191 | 2 | 6/1 |

| Azusa | 123.3 | 7 | .1327 | .3980 | 115.0 | 4460 | .163 | .195 | 256 | 1/0 | 6/1 |

| Anaheim | 155.4 | 7 | .1490 | .4470 | 144.9 | 5390 | .130 | .154 | 296 | 2/0 | 6/1 |

| Amherst | 195.7 | 7 | .1672 | .5020 | 182.5 | 6790 | .103 | .123 | 342 | 3/0 | 6/1 |

| Alliance | 246.9 | 7 | .1878 | .5630 | 230.2 | 8560 | .0816 | .0973 | 395 | 4/0 | 6/1 |

| Butte | 312.8 | 19 | .1283 | .6420 | 291.7 | 11000 | .0644 | .0769 | 460 | 266.8 | 26/7 |

| Canton | 394.5 | 19 | .1441 | .7200 | 367.9 | 13300 | .0511 | .0610 | 532 | 336.4 | 26/7 |

| Cairo | 465.4 | 19 | .1565 | .7830 | 434.0 | 15600 | .0433 | .0518 | 590 | 397.5 | 26/7 |

| Darien | 559.5 | 19 | .1716 | .8580 | 521.7 | 18800 | .0360 | .0431 | 663 | 477.0 | 26/7 |

| Elgin | 652.4 | 19 | .1853 | .9270 | 608.4 | 21900 | .0309 | .0371 | 729 | 556.5 | 26/7 |

| Flint | 740.8 | 37 | .1415 | .9900 | 690.8 | 24400 | .0272 | .0327 | 790 | 636.0 | 26/7 |

| Greeley | 927.2 | 37 | .1583 | 1.1080 | 864.6 | 30500 | .217 | .0263 | 908 | 795.0 | 26/7 |

| Code Word | Conductor size | Stranding | Sectional Area | Diameter of Conductor | Linear Density | Rated Strength | D.C. Resistance at 20°C | Curren Rating |

|---|---|---|---|---|---|---|---|---|

| mm 2 | No. /mm | mm 2 | mm | kg/km | kgf | Ω/km | A | |

| Box | 15 | 7/1.85 | 18.82 | 5.55 | 51 | 537 | 1.7495 | 93 |

| Acacia | 20 | 7/2.08 | 23.79 | 6.24 | 65 | 680 | 1.384 | 110 |

| Almond | 25 | 7/2.34 | 30.1 | 7.02 | 82 | 861 | 1.0934 | 128 |

| Cedar | 30 | 7/2.54 | 35.47 | 7.62 | 97 | 1014 | 0.9281 | 132 |

| Deodar | 35 | 7/2. 77 | 42.18 | 8.31 | 115 | 1205 | 0.7804 | 148 |

| Fir | 40 | 7/2.95 | 47.84 | 8.85 | 131 | 1367 | 0.688 | 161 |

| Hazel | 50 | 7/3.30 | 59.87 | 9.9 | 164 | 1711 | 0.5498 | 184 |

| Pine | 60 | 7/3.61 | 71.65 | 10.83 | 196 | 2048 | 0.4594 | 204 |

| Holly | 70 | 7/3.91 | 84.05 | 11.73 | 230 | 2402 | 0.3917 | 222 |

| Willow | 75 | 7/4. 04 | 89.73 | 12.12 | 245 | 2565 | 0.3669 | 233 |

| 80 | 7/4.19 | 96.52 | 12.57 | 264 | 2758 | 0.3441 | 250 | |

| 90 | 7/4.44 | 108 | 13.32 | 298 | 3112 | 0.3023 | 260 | |

| Oak | 100 | 7/4.65 | 118.9 | 13.95 | 325 | 3398 | 0.2769 | 272 |

| 100 | 19/2.82 | 118.7 | 14.1 | 326 | 3393 | 0.2787 | 270 | |

| Mulberry | 125 | 19/3.18 | 150. 90 | 15.9 | 415 | 4312 | 0.2192 | 319 |

| Ash | 150 | 19/3.48 | 180.7 | 17.4 | 497 | 5164 | 0.1831 | 354 |

| Elm | 175 | 19/3.76 | 211 | 18.8 | 580 | 6030 | 0.1568 | 385 |

| Poplar | 200 | 37/2.87 | 239.4 | 20.09 | 659 | 8841 | 0.1385 | 414 |

| 225 | 37/3.05 | 270.3 | 21.35 | 744 | 7724 | 0.1227 | 430 | |

| Sycamore | 250 | 37/3.22 | 303.2 | 22.54 | 835 | 8664 | 0.1093 | 487 |

| Upas | 300 | 37/3.53 | 362.1 | 24.71 | 997 | 10350 | 0.09156 | 527 |

| Walnut | 350 | 37/3.81 | 421.8 | 26.67 | 1162 | 12053 | 0.0786 | 610 |

| Yew | 400 | 37/4.06 | 479 | 28.42 | 1319 | 13685 | 0.06921 | 629 |

| Totara | 425 | 37/4.14 | 498.1 | 28.98 | 1372 | 14233 | 0.06656 | 640 |

| Rubus | 500 | 61/3.50 | 586.9 | 31.5 | 1620 | 16771 | 0.05662 | 760 |

| Araucaria | 700 | 61/4.14 | 821.1 | 37.26 | 2266 | 23450 | 0.04047 | 842 |

| Code number | Area | Number of wires | Diameter of wire | Diameter of conductor | Linear mass | Rated strength | D.C. resistance | |

|---|---|---|---|---|---|---|---|---|

| mm 2 | mm | mm | Kg/km | kN | Ω/km | |||

| 16 | 18.6 | 7 | 1.84 | 5.52 | 50.8 | 6.04 | 1.7896 | |

| 25 | 29 | 7 | 2.3 | 6.9 | 79.5 | 9.44 | 1.1453 | |

| 40 | 46.5 | 7 | 2.91 | 8.73 | 127.1 | 15.1 | 0.7158 | |

| 63 | 73.2 | 7 | 3.65 | 10.95 | 200.2 | 23.06 | 0.4545 | |

| 100 | 11 | 19 | 2.79 | 13.95 | 319.3 | 37.76 | 0.2877 | |

| 125 | 145 | 19 | 3.12 | 15.6 | 399.2 | 47.2 | 0.2302 | |

| 160 | 18 | 19 | 3.53 | 17.65 | 511 | 58.56 | 0.1798 | |

| 200 | 232 | 19 | 3.95 | 19.75 | 638.7 | 73.2 | 0.1439 | |

| 250 | 290 | 19 | 4.41 | 22.05 | 798.4 | 91.5 | 0.1151 | |

| 315 | 366 | 37 | 3.55 | 24.85 | 1008.4 | 115.29 | 0. 0916 | |

| 400 | 465 | 37 | 4 | 28 | 1280.5 | 146.4 | 0.0721 | |

| 450 | 523 | 37 | 4.24 | 29.68 | 1440.5 | 164.7 | 0.0641 | |

| 500 | 581 | 37 | 4.47 | 31.29 | 1600.6 | 183 | 0.0577 | |

| 560 | 651 | 61 | 3.69 | 33.21 | 1795.3 | 204.95 | 0.0516 | |

| 630 | 732 | 61 | 3.91 | 35.19 | 2019.8 | 230.58 | 0.0458 | |

| 710 | 825 | 61 | 4.15 | 37.35 | 2276.2 | 259.86 | 0.0407 | |

| 800 | 930 | 61 | 4.4 | 39.6 | 2564.8 | 292.8 | 0.0361 | |

| 900 | 1046 | 91 | 3.83 | 42.13 | 2888.3 | 329.4 | 0.0321 | |

| 1000 | 1162 | 91 | 4.03 | 44.33 | 3209.3 | 366 | 0.0289 | |

| 1120 | 1301 | 91 | 4.27 | 46.97 | 3594.4 | 409.92 | 0.0258 |

| Conductor size mm 2 | Alloy area mm 2 | Number of wires | Diameter of wire mm | Overall diameter of conductor mm | Linear mass kg/km | Rated tensile strength daN | Maximum resistance D.C. at 20 ℃ Ω/km | Current Rating A |

|---|---|---|---|---|---|---|---|---|

| 16 | 15.89 | 7 | 1.7 | 5.1 | 43 | 444 | 2.091 | 105 |

| 25 | 24.25 | 7 | 2.1 | 6.3 | 66 | 677 | 1.3703 | 135 |

| 35 | 34.36 | 7 | 2.5 | 7.5 | 94 | 960 | 0.9669 | 170 |

| 50 | 49.48 | 7 | 3 | 9 | 135 | 1382 | 0.6714 | 210 |

| 50 | 48.35 | 19 | 1.8 | 9 | 133 | 1350 | 0.6905 | 210 |

| 70 | 65.81 | 19 | 2.1 | 10.5 | 181 | 1838 | 0.5073 | 255 |

| 95 | 93.27 | 19 | 2.5 | 12.5 | 256 | 2605 | 0.3579 | 320 |

| 120 | 116.99 | 19 | 2.8 | 14 | 322 | 3268 | 0.2854 | 365 |

| 150 | 147.11 | 37 | 2.25 | 15.8 | 406 | 4109 | 0.2274 | 425 |

| 185 | 181.62 | 37 | 2.5 | 17.5 | 500 | 5073 | 0.1842 | 490 |

| 240 | 242.54 | 61 | 2.25 | 20.3 | 670 | 6774 | 0.1383 | 585 |

| 300 | 299.43 | 61 | 2.5 | 22.5 | 827 | 8363 | 0.112 | 670 |

| 400 | 400.14 | 61 | 2.89 | 26 | 1104 | 11176 | 0.0838 | 810 |

| 500 | 499.63 | 61 | 3.23 | 29.1 | 1379 | 13960 | 0.06709 | 930 |

| 625 | 626.2 | 91 | 2.96 | 32.6 | 1732 | 17490 | 0.054 | 1075 |

| 800 | 802.09 | 91 | 3.35 | 36.9 | 2218 | 22402 | 0.0418 | 1255 |

| 1000 | 999.71 | 91 | 3.74 | 41.1 | 2767 | 27922 | 0.0335 | 1450 |

| Conductor size | Stranding | Section area | Diameter of conductor | Linear mass | Rated strength | D.C. resistance at 20 ℃ | Current Rating |

|---|---|---|---|---|---|---|---|

| MCM | No./mm | mm2 | mm | Kg/km | kgf | Ω/km | A |

| 19 | 7/1.32 | 9.5 | 3.96 | 26 | 290 | 3.416 | 55 |

| 24 | 7/1.48 | 12 | 4.44 | 33 | 360 | 2.71 | 69 |

| 30 | 7/1.66 | 15.2 | 4.98 | 41 | 460 | 2.148 | 79 |

| 38 | 7/1.86 | 19.1 | 5.58 | 52 | 580 | 1.703 | 93 |

| 48 | 7/2.09 | 24.1 | 6.27 | 66 | 730 | 1.352 | 108 |

| 60 | 7/2.35 | 30.4 | 7.05 | 83 | 920 | 1.072 | 126 |

| 76 | 7/2.64 | 38.3 | 7.92 | 105 | 1160 | 0.8494 | 139 |

| 95 | 7/2.96 | 48.3 | 8.88 | 132 | 1470 | 0.6742 | 161 |

| 120 | 7/3.33 | 61 | 9.99 | 166 | 1850 | 0.5344 | 186 |

| 152 | 7/3.74 | 76.8 | 11.22 | 210 | 2330 | 0.4238 | 211 |

| 192 | 7/4.20 | 97 | 12.6 | 265 | 2940 | 0.3355 | 242 |

| 241 | 7/4.72 | 122.3 | 14.15 | 334 | 3710 | 0.2666 | 276 |

| 241 | 19/2.86 | 122.3 | 14.3 | 335 | 3710 | 0.2678 | 280 |

| 304 | 19/3.21 | 154.1 | 16.05 | 423 | 4670 | 0.2125 | 321 |

| 342 | 19/3.41 | 173.4 | 17.05 | 475 | 5260 | 0.1889 | 343 |

| 384 | 19/3.61 | 194.4 | 18.05 | 533 | 5890 | 0.1684 | 369 |

| 453 | 19/3.92 | 229.7 | 19.6 | 629 | 6970 | 0.1423 | 404 |

| 544 | 19/4.30 | 275.7 | 21.5 | 756 | 8360 | 0.1187 | 451 |

| 570 | 37/3.15 | 288.8 | 22.05 | 796 | 8760 | 0.1137 | 464 |

| 635 | 37/3.33 | 321.5 | 23.31 | 885 | 9740 | 0.1026 | 497 |

| 725 | 37/3.56 | 367.4 | 24.92 | 1012 | 11140 | 0.0895 | 533 |

| 816 | 37/3.77 | 413.5 | 26.39 | 1140 | 12540 | 0.0795 | 577 |

| 856 | 37/3.86 | 433.7 | 27.02 | 1195 | 13140 | 0.0758 | 594 |

| 907 | 37/3.98 | 459.4 | 27.86 | 1266 | 13920 | 0.0714 | 614 |

| 997 | 37/4.16 | 505.2 | 29.12 | 1391 | 15320 | 0.065 | 648 |

Delivers high-quality AAAC Conductor to customers worldwide.

Enquire Now!First of all, aaac has higher strength and corrosion resistance than aac and acsr conductor. The aaac conductor has high strength than aac conductor, that is to say, the aluminum alloy conductor allows a long span. And because there is no steel core in aluminum alloy conductor, the aaac has more excellent corrosion resistance than acsr. So it can even be used in sea coat area and polluted industrial areas. If the overhead line needs to cover a long distance and requires for high corrosion resistance, the all aluminum conductor, like conductor flint and aaac greeley will be your good choice.

Besides, the aluminum alloy conductor has excellent conductivity. On the one hand,the aaac cable has strong current carrying capacity. On the other hand, aaac wire is homogeneous, so there is lower electrical less during the transmission process. This performance is what we need.

Because the aaac wire owns the definitely advantages, and the aluminum is similar with aluminum alloy. So some conductor aaac manufacturers may use the aluminum to replace the aluminum alloy, or the quality of the aluminum alloy is not so good. For the long-term cooperation, we never do the things, which may break the customer. You can find in the aaac conductor catalogue. Galaxy Electric is indeed a very reliable company. In the aaac conductor price list, you may find the aaac conductor manufacturers india are very cheap. But you may know the cheapest aluminum is in China. And in China, the aluminum of Henan is the cheapest. Galaxy Electric is located in Henan, so choose Galaxy Electric, you can get the best price.

As we all know, Cable AAAC has different standards and types, so the demands of customers are different. Every AAAC wire has a code name or number. When you purchase the conductor AAAC, you just need speak the the code, the seller will know what you want. If you don’t know the exact code name, it doesn’t matter. As long as you know AAAC conductor specifications, as professional aac manufacturers, Galaxy Electric Group can customize for you.

The price of AAAC conductor can vary widely depending on various factors, including the specific alloy composition, the size and length of the conductor, and the supplier’s location and pricing strategy. Other factors such as market demand, availability of raw materials, and transportation costs can also impact the price of AAAC conductor.

With over 30,000 products sold annually, JYTOP Cable provides its customers with knowledgeable market and product application experts, standard same-day shipments, 99.99% order accuracy and on-time delivery, and 24/7/365 service.

Contact our trained experts today to find your perfect power solution.

Request a quote