JYTOP is a leading manufacturer of AACSR Conductor in the field of power transmission and distribution

With over 30 years production experience and 15 years export experience, factory price without any third party. Can be customized your ideal size,meets or exceeds the requirements of all international standards like ASTM, AS, BS, CSA, DIN, IEC, NFC, SS -etc

JYTOP's AACSR Conductor have been exported to many countries and regions such as the Middle Est, Africa, Asia Oceania, South America, North America etc., and have won praise from domestic and foreign customers.

In this page, we'll introduce AACSR Conductor and their advantages, applications, standards and frequently asked questions.

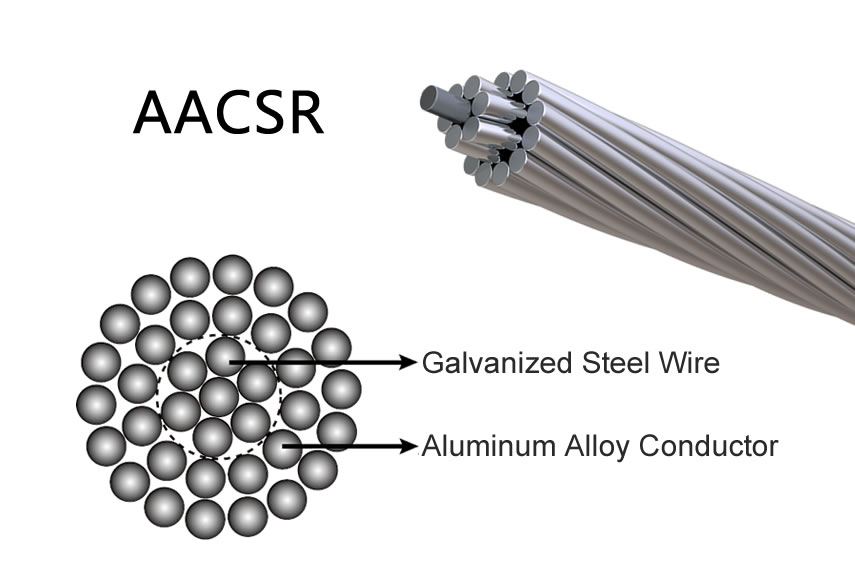

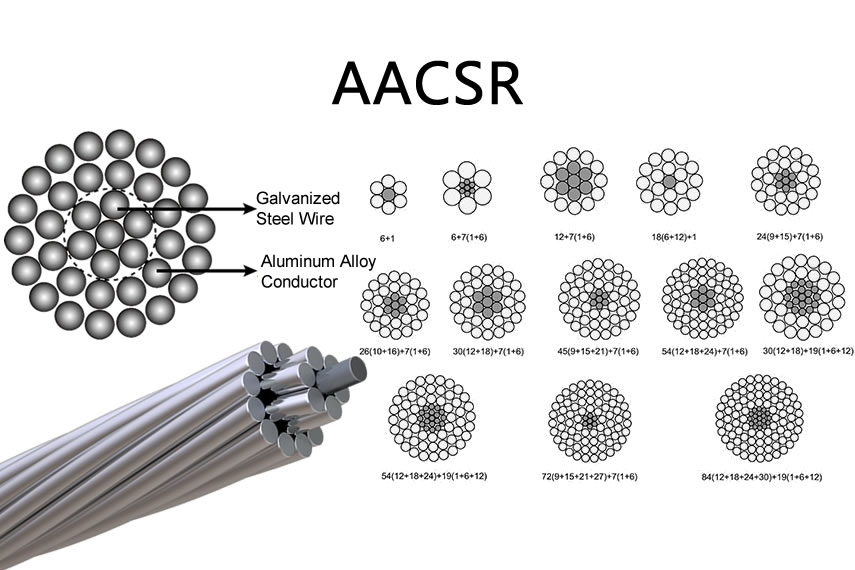

AACSR stands for Aluminum Alloy Conductor Steel Reinforced. It is a type of overhead electrical conductor used for power transmission and distribution lines. AACSR conductors are designed to combine the strength of steel with the lightweight properties of aluminum, resulting in a conductor that is both strong and efficient.

Overall, AACSR conductors are a reliable and efficient choice for overhead power transmission and distribution systems, offering a balance between mechanical strength, electrical conductivity, and weight.

Aluminum Alloy Conductor Steel Reinforced,AACSR Conductor,AACSR Cable,AACSR wire.

JYTOP manufacture and supply AACSR Cable on Non-Returnable wooden/steel reels or Returnable steel reels depending on customer requirement.

JYTOP can produce AACSR according to various domestic and international standards and customer requirements, including ASTM IEC and other standards. We can also provide customized services according to customer’s special requirements to meet the needs of different customers.

Get all the answers to the most frequently asked questions (FAQs) regarding AACSR Cable sizes,AACSR Cable full form,AACSR Conductor size chart,AACSR Conductor chart,AACSR Conductor sizes,AACSR Conductor size chart,AACSR Conductor full form,AACSR Conductor ampacity,AACSR Conductor diameter,AACSR Conductor types,AACSR Conductor data sheet and much, much more.

| Nominal Sectional Area | No. / Nominal Dia. of Wire | Approx. Overall Dia. | Approx. Weight | Nominal Breaking Load | Max. DC Resistance at 20°C | |||

|---|---|---|---|---|---|---|---|---|

| Aluminum Alloy | Steel | Total | Aluminum Alloy | Steel | ||||

| mm2 | mm2 | mm2 | No./mm | No./mm | mm | kg/km | kN | Ω/km |

| 140 | 23 | 163 | 26/2.62 | 7/2.04 | 16.6 | 565 | 75 | 0.23898 |

| 140 | 33 | 173 | 30/2.44 | 7/2.44 | 17.1 | 643 | 87.4 | 0.23906 |

| 160 | 26 | 186 | 26/2.80 | 7/2.18 | 17.7 | 646 | 85.6 | 0.20924 |

| 160 | 38 | 198 | 30/2.61 | 7/2.61 | 18.3 | 736 | 106 | 0.20893 |

| 180 | 29 | 209 | 26/2.97 | 7/2.31 | 18.8 | 731 | 95.1 | 0.18597 |

| 180 | 42 | 222 | 30/2.76 | 7/2.76 | 19.3 | 823 | 112 | 0.18684 |

| 200 | 32 | 232 | 26/3.13 | 7/2.43 | 19.8 | 805 | 106 | 0.16744 |

| 200 | 47 | 247 | 30/2.91 | 7/2.91 | 20.4 | 915 | 124 | 0.16807 |

| 224 | 36 | 260 | 26/3.31 | 7/2.57 | 21.0 | 901 | 118 | 0.14973 |

| 224 | 52 | 276 | 30/3.08 | 7/3.08 | 21.6 | 1025 | 139 | 0.15003 |

| 250 | 41 | 291 | 26/3.50 | 7/2.72 | 22.2 | 1008 | 129 | 0.13391 |

| 250 | 58 | 308 | 30/3.26 | 7/3.26 | 22.8 | 1149 | 156 | 0.13392 |

| 280 | 46 | 326 | 26/3.70 | 7/2.88 | 23.4 | 1127 | 144 | 0.11983 |

| 280 | 65 | 345 | 30/3.45 | 7/3.45 | 24.2 | 1286 | 171 | 0.11958 |

| 315 | 52 | 367 | 26/3.93 | 7/3.06 | 24.9 | 1272 | 163 | 0.10621 |

| 315 | 72 | 387 | 30/3.66 | 19/2.20 | 25.6 | 1438 | 190 | 0.12246 |

| 355 | 58 | 413 | 26/4.17 | 7/3.24 | 26.4 | 1430 | 183 | 0.09434 |

| 355 | 81 | 436 | 30/3.88 | 19/2.33 | 27.2 | 1614 | 211 | 0.10897 |

| 400 | 65 | 465 | 26/4.43 | 7/3.45 | 28.1 | 1616 | 207 | 0.08359 |

| 400 | 91 | 491 | 30/4.12 | 19/2.47 | 28.8 | 1818 | 237 | 0.09664 |

| 450 | 59 | 509 | 54/3.26 | 19/1.98 | 29.5 | 1706 | 215 | 0.08952 |

| 500 | 63 | 563 | 54/3.43 | 19/2.06 | 30.9 | 1878 | 229 | 0.08086 |

| 560 | 71 | 631 | 54/3.63 | 19/2.18 | 32.7 | 2104 | 257 | 0.07220 |

| 630 | 80 | 710 | 54/3.85 | 19/2.31 | 34.6 | 2365 | 286 | 0.06418 |

| 710 | 90 | 800 | 54/4.09 | 19/2.45 | 36.8 | 2664 | 322 | 0.05687 |

| 800 | 101 | 901 | 54/4.34 | 19/2.60 | 39.0 | 3003 | 363 | 0.05051 |

| 900 | 73 | 973 | 84/3.69 | 19/2.21 | 40.6 | 3060 | 355 | 0.05809 |

| 1000 | 81 | 1081 | 84/3.89 | 19/2.33 | 42.8 | 3400 | 391 | 0.05227 |

| 1120 | 91 | 1211 | 84/4.12 | 19/2.47 | 45.3 | 3816 | 439 | 0.04660 |

| 1250 | 102 | 1352 | 84/4.35 | 19/2.61 | 47.8 | 4255 | 490 | 0.04180 |

| Code Number | Nominal Area | No. / Nominal Dia. of Wire | Approx. Overall Dia. | Approx. Weight | Nominal Breaking Load | Max. DC Resistance at 20°C | |||

|---|---|---|---|---|---|---|---|---|---|

| Aluminum Alloy | Steel | Total | Aluminum Alloy | Steel | |||||

| mm2 | mm2 | mm2 | No./mm | No./mm | mm | kg/km | kN | Ω/km | |

| 16 | 18.4 | 3.07 | 21.5 | 6/1.98 | 1/1.98 | 5.94 | 74.4 | 9.02 | 1.7934 |

| 25 | 28.8 | 4.8 | 33.6 | 6/2.47 | 1/2.47 | 7.41 | 116.2 | 13.96 | 1.1478 |

| 40 | 46 | 7.67 | 53.7 | 6/3.13 | 1/3.13 | 9.39 | 185.9 | 22.02 | 0.7174 |

| 63 | 72.5 | 12.1 | 84.6 | 6/3.92 | 1/3.92 | 11.8 | 292.8 | 34.68 | 0.4555 |

| 100 | 115 | 6.39 | 121 | 18/2.85 | 1/2.85 | 14.3 | 366.4 | 41.24 | 0.2880 |

| 125 | 144 | 7.99 | 152 | 18/3.19 | 1/3.19 | 16.0 | 458.0 | 51.23 | 0.2304 |

| 125 | 144 | 23.4 | 167 | 26/2.65 | 7/2.06 | 16.8 | 579.9 | 69.86 | 0.2310 |

| 160 | 184 | 10.2 | 194 | 18/3.61 | 1/3.61 | 18.0 | 586.2 | 65.58 | 0.1800 |

| 160 | 184 | 30.0 | 214 | 26/3.00 | 7/2.34 | 19.0 | 742.3 | 88.52 | 0.1805 |

| 200 | 230 | 12.8 | 243 | 18/4.04 | 1/4.04 | 20.2 | 732.8 | 81.97 | 0.1440 |

| 200 | 230 | 37.5 | 268 | 26/3.36 | 7/2.61 | 21.3 | 927.9 | 110.64 | 0.1444 |

| 250 | 288 | 28.3 | 316 | 22/4.08 | 7/2.27 | 23.1 | 1013.5 | 117.09 | 0.1154 |

| 250 | 288 | 46.9 | 335 | 26/3.75 | 7/2.92 | 23.8 | 1159.8 | 138.31 | 0.1155 |

| 315 | 363 | 25.1 | 388 | 45/3.20 | 7/2.14 | 25.6 | 1196.5 | 136.28 | 0.0917 |

| 315 | 363 | 59.0 | 422 | 26/4.21 | 7/3.28 | 26.7 | 1461.4 | 171.90 | 0.0917 |

| 400 | 460 | 31.8 | 492 | 45/3.61 | 7/2.41 | 28.9 | 1519.4 | 172.10 | 0.0722 |

| 400 | 460 | 59.7 | 520 | 54/3.29 | 7/3.29 | 29.7 | 1738.3 | 201.46 | 0.0723 |

| 450 | 518 | 35.8 | 554 | 45/3.83 | 7/2.55 | 30.6 | 1709.3 | 193.61 | 0.0642 |

| 450 | 518 | 67.1 | 585 | 54/3.49 | 7/3.49 | 31.5 | 1955.6 | 226.64 | 0.0643 |

| 500 | 575 | 39.8 | 615 | 45/4.04 | 7/2.69 | 32.3 | 1899.3 | 215.12 | 0.0578 |

| 500 | 575 | 74.6 | 650 | 54/3.68 | 7/3.68 | 33.2 | 2172.9 | 251.82 | 0.0578 |

| 560 | 645 | 44.6 | 689 | 45/4.27 | 7/2.85 | 34.2 | 2127.2 | 240.93 | 0.0516 |

| 560 | 645 | 81.6 | 726 | 54/3.90 | 7/2.34 | 35.1 | 2420.9 | 283.21 | 0.0516 |

| 630 | 725 | 31.3 | 756 | 72/3.58 | 7/2.39 | 35.8 | 2248.0 | 249.62 | 0.0459 |

| 630 | 725 | 91.8 | 817 | 54/4.13 | 7/2.48 | 37.2 | 2732.5 | 318.61 | 0.0459 |

| 710 | 817 | 35.3 | 852 | 72/3.80 | 7/2.53 | 38.0 | 2533.4 | 281.32 | 0.0407 |

| 710 | 817 | 104 | 921 | 54/4.39 | 19/2.63 | 39.5 | 3069.4 | 359.06 | 0.0407 |

| 800 | 921 | 39.8 | 961 | 72/4.04 | 7/2.69 | 40.4 | 2854.6 | 316.98 | 0.0361 |

| 800 | 921 | 76.7 | 997 | 84/3.74 | 7/3.74 | 41.1 | 3145.1 | 356.03 | 0.0362 |

| 900 | 1036 | 44.8 | 1081 | 72/4.28 | 7/2.85 | 42.8 | 3211.4 | 356.60 | 0.0321 |

| 900 | 1036 | 86.3 | 1122 | 84/3.96 | 7/3.96 | 43.6 | 3538.3 | 400.53 | 0.0322 |

| 1000 | 1151 | 93.7 | 1245 | 84/4.18 | 19/2.51 | 45.9 | 3916.8 | 446.37 | 0.0289 |

| 1120 | 1289 | 105 | 1394 | 84/4.42 | 19/2.65 | 48.6 | 4386.8 | 499.93 | 0.0258 |

| Code Name | No. / Nominal Dia. of Wire | Cross Section Area | Approx. Overall Dia. | Approx. Weight | Nominal Breaking Load | Max. DC Resistance at 20°C | |||

|---|---|---|---|---|---|---|---|---|---|

| Aluminum Alloy | Steel | Aluminum Alloy | Steel | Total | |||||

| No./mm | No./mm | mm2 | mm2 | mm2 | mm | kg/km | kN | Ω/km | |

| Apple 1120 | 6/3.00 | 1/3.00 | 42.4 | 7.1 | 49.5 | 9.0 | 171 | 18.3 | 0.7000 |

| Banana 1120 | 6/3.75 | 1/3.75 | 66.3 | 11.0 | 77.3 | 11.3 | 268 | 27.9 | 0.4480 |

| Cherry 1120 | 6/4.75 | 7/1.60 | 106 | 14.1 | 14.3 | 14.3 | 402 | 40.7 | 0.2790 |

| Grape 1120 | 30/2.50 | 7/2.50 | 147 | 34.4 | 17.5 | 17.5 | 677 | 74.4 | 0.2030 |

| Lemon 1120 | 30/3.00 | 7/3.00 | 212 | 49.5 | 21.0 | 21.0 | 973 | 107 | 0.1410 |

| Lychee 1120 | 30/3.25 | 7/3.25 | 249 | 58.1 | 22.8 | 22.8 | 1140 | 126 | 0.1200 |

| Lime 1120 | 30/3.50 | 7/3.50 | 289 | 67.3 | 24.5 | 24.5 | 1320 | 143 | 0.1040 |

| Mango 1120 | 54/3.00 | 7/3.00 | 382 | 49.5 | 27.0 | 27.0 | 1440 | 149 | 0.0784 |

| Orange 1120 | 54/3.25 | 7/3.25 | 448 | 58.1 | 29.3 | 29.3 | 1690 | 174 | 0.0669 |

| Olive 1120 | 54/3.50 | 7/3.50 | 519 | 67.3 | 31.5 | 31.5 | 1960 | 197 | 0.0578 |

| Equal steel and Aluminum wire diameter | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Code Name | Size | Al Alloy Area | Steel Wire Area | No. Of Al Alloy Wires | No. Of St | Dia of Wire | Overall Dia of Conductor | Tens Str of Al Alloy | Tens Str of Steel | Rated Str of Conductor | Max DC Resist at 20 0C | Linear Weight | Elasticity Mod * | Coefficient Of Linear Expansion |

| Mrn2 | mm2 | Wires | mm | mm | hbar | hbar | daN | Ω /km | Kg/km | hbar | / 0C | |||

| PHLOX | 37.7 | 28.27 | 9.42 | 9 | 3 | 2 | 8.3 | 32.4 | 156.8 | 2360 | 1.17 | 155 | 9300 | 17.0 x 10-1 |

| PHLOX | 59.7 | 37.7 | 21.99 | 12 | 7 | 2 | 10 | 32.4 | 156.8 | 4560 | 0.88 | 276 | 10800 | 15.3 x 106 |

| PHLOX | 75.5 | 47.71 | 27.83 | 12 | 7 | 2.25 | 11.25 | 32.4 | 156.8 | 5770 | 0.695 | 348 | 10800 | 15.3 X 10-6 |

| PHLOX | 116.2 | 56.55 | 59.69 | 18 | 19 | 2 | 14 | 32.4 | 156.8 | 10815 | 0.58 | 636 | 12400 | 14.2 x 10-6 |

| PHLOX | 147.1 | 71.57 | 75.54 | 18 | 19 | 2.25 | 15.75 | 32.4 | 156.8 | 13685 | 0.466 | 802 | 12400 | 14.2 X 10-6 |

| PASTEL | 147.1 | 119.28 | 27.83 | 30 | 7 | 2.25 | 15.75 | 32.4 | 156.8 | 8185 | 0.279 | 547 | 8400 | 18.1 x 10-6 |

| PHLOX | 181 | 88.36 | 93.27 | 18 | 19 | 2.5 | 17.5 | 32.4 | 156.8 | 16895 | 0.378 | 990 | 12400 | 14.2 x 10 6 |

| PASTEL | 181.6 | 147.26 | 34.36 | 30 | 7 | 2.5 | 17.5 | 32.4 | 156.8 | 10120 | 0.227 | 675 | 8400 | 18.1 x 10-1 |

| PHLOX | 228 | 110.83 | 116.99 | 18 | 19 | 2.8 | 19.6 | 32.4 | 156.8 | 21200 | 0.3 | 1244 | 12400 | 14.2 x 10-1 |

| PASTEL | 228 | 184.72 | 43.1 | 30 | 7 | 2.8 | 19.6 | 32.4 | 156.8 | 12680 | 0.18 | 848 | 8400 | 18.1 x 101 |

| PHLOX | 288 | 140.28 | 148.07 | 18 | 19 | 3.15 | 22.05 | 32.4 | 156.8 | 26800 | 0.237 | 1570 | 12400 | 14.2 x 101 |

| PASTEL | 288 | 233.8 | 54.55 | 30 | 7 | 3.15 | 22.05 | 32.4 | 156.8 | 16050 | 0.142 | 1074 | 8400 | 18.0 x 101 |

| PASTEL | 299 | 205.17 | 93.27 | 42 | 19 | 2.5 | 22.5 | 32.4 | 156.8 | 20875 | 0.162 | 1320 | 9650 | 16.3 x 10-1 |

| PHLOX | 376 | 147.78 | 227.83 | 24 | 37 | 2.8 | 25.2 | 32.4 | 156.8 | 38960 | 0.225 | 2211 | 13000 | 13.5 x 10-1 |

| Non-equal steel and aluminum wire diameter | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Code Name | Totall area | AI Alloy Area | Stell Area | No.&Dia Of Ai Alloy | No.& Dia Of Ai Stell | Overal Dia of Conductor | Tens Str of Al Alloy | Tens Str of Steel | Rated Str of Conductor | Max DC Resist at 20 0C | Linear Weight | Elast Mod * | Coefficient Of Linear Expansion |

| Mm2 | mm² | mm² | wires | wires | mm | hbar | hbar | daN | Ω /km | Kg/km | hbar | */ oC | |

| PHLOX | 94.1 | 51.95 | 42.12 | 15x 2.10 | 19x 1.68 | 12.8 | 32.4 | 156.8 | 8035 | 0.642 | 481 | 11200 | 14.7 x 10 1 |

| PASTEL | 412 | 325.72 | 85.95 | 32x 3.60 | 19x 2.40 | 26.4 | 32.4 | 156.8 | 23830 | 0.103 | 1593 | 8200 | 17.8 x 10-1 |

| PETUNIA | 612 | 507.8 | 104.79 | 66x 3.13 | 19x 2.65 | 32.1 | 32.4 | 156.8 | 32830 | 0.0657 | 2241 | 7750 | 18.6 x 10-1 |

| PETUNIA | 865 | 717.33 | 148.06 | 66x 3.725 | 19x 3.10 | 38.1 | 32.4 | 156.8 | 46000 | 0.0465 | 3174 | 7750 | 18.5 x 10-1 |

| 54x 2.80 | |||||||||||||

| POLYGONM | 1185 | 956.66 | 227.82 | 66x 3.47 | 37x 2.80 | 44.7 | 32.4 | 156.8 | 66385 | 0.0349 | 4475 | 7750 | 18.1 x 10-1 |

Delivers high-quality AACSR Conductor to customers worldwide.

Enquire Now!With over 30,000 products sold annually, JYTOP Cable provides its customers with knowledgeable market and product application experts, standard same-day shipments, 99.99% order accuracy and on-time delivery, and 24/7/365 service.

Contact our trained experts today to find your perfect power solution.

Request a quote